What are the advantages and disadvantages of PS plastic compared with other common plastics?

Release Time : 2025-04-10

As a widely used thermoplastic, PS plastic has its own unique performance characteristics and application areas. However, compared with other common plastics, PS plastic shows obvious advantages in some aspects, while it also has certain limitations in other aspects.

First of all, from the advantages, a notable feature of PS plastic is its high transparency, which makes it very suitable for manufacturing products that require clear visual effects, such as food packaging, display boxes and disposable tableware. In addition, PS plastic has good rigidity and hardness, which makes it excellent in making structural parts, such as model toys and household appliance housings. Due to its simple molding process and low cost, PS plastic is widely used in the production of daily necessities and industrial parts, which can meet the economic needs of large-scale production.

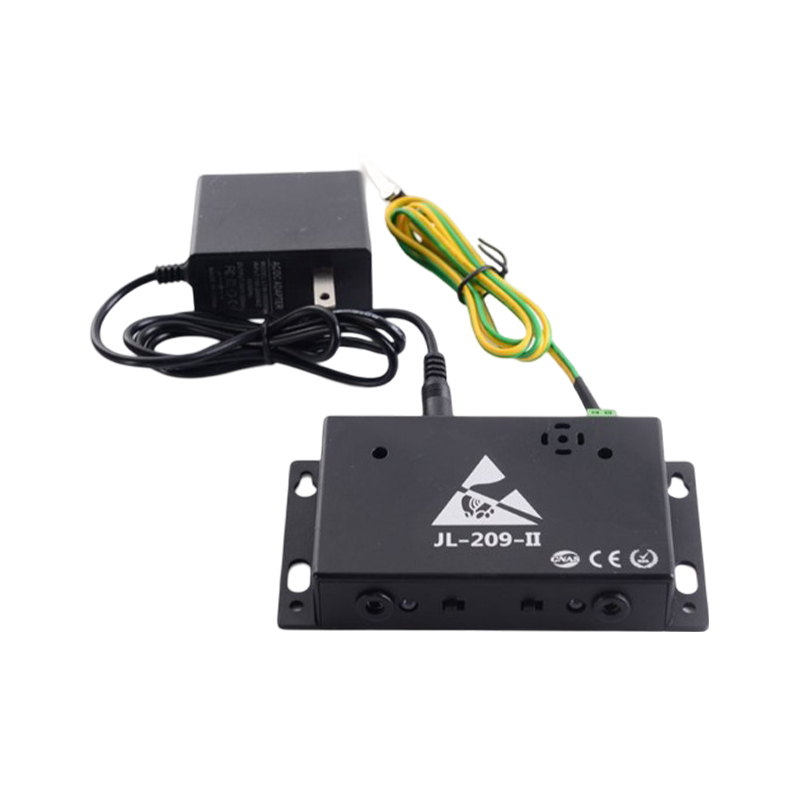

Secondly, the electrical insulation properties of PS plastic are also excellent, which is suitable for the encapsulation and protection of electronic components. Its low hygroscopicity means that it can maintain stable electrical properties even in a humid environment, which is crucial for electronic equipment. In addition, PS plastic also has good chemical corrosion resistance and can withstand many common acid and alkali solutions, so it has certain application potential in the chemical industry.

However, PS plastic also has its shortcomings. One major drawback is that it is brittle and easily breaks when impacted or in low-temperature environments. This feature limits its use in some applications that require higher toughness. To overcome this problem, toughening agents or other modification methods are usually added to improve its impact strength, but this will also increase the cost and complexity of the material accordingly.

In addition, PS plastic has poor thermal stability. When the temperature exceeds 80 degrees Celsius, its physical properties will drop rapidly and softening and deformation may occur. This means that special attention should be paid when using it in high-temperature environments to avoid product failure due to overheating. In contrast, plastics such as polypropylene have better heat resistance and can work stably in a higher temperature range.

In terms of environmental protection, PS plastic also faces challenges. Because its molecular chain is relatively regular and not easily degraded by microorganisms, its disposal after disposal becomes a major problem. Although PS plastic can be recycled and reused mechanically, it is often difficult to achieve efficient recycling in actual operations due to pollution or the presence of mixed materials. In contrast, some new bio-based plastics show better degradability, which helps reduce environmental pollution.

It is worth noting that although PS plastic itself is not flame retardant, it can achieve a certain fire resistance level and meet the requirements of specific safety standards after adding flame retardants. However, this may affect other properties of the material and increase additional costs.

In general, PS plastic occupies an important position in many industries due to its advantages such as high transparency, strong rigidity, good electrical insulation and low cost. However, its brittleness, poor thermal stability and difficulty in environmental protection treatment cannot be ignored. In view of these shortcomings, the application scope of PS plastic can be effectively expanded and its comprehensive performance can be improved by modifying the material or selecting suitable substitutes. With the advancement of technology, it is expected that more environmentally friendly and high-performance PS plastic variants will be developed in the future to further promote its application in various fields.